Camera-based In-Line Inspection of Machine Parts

Customer: Automotive Supplier

During this project, a software was developed that allows the automatic inspection of machine parts surfaces. The software manages the full inspection process, starting with the camera recording, image processing and anomaly evaluation, up to the communication with the factory and conveyor system.

Project Context

Quality assurance is a central objective in the area of automated production. Manual inspection of machine parts can quickly reach its limits, e.g., in case of large quantities or high-precision requirements. In some unfavorable production scenarios, it may only be possible to manually inspect random samples.

Automated camera-based inspection systems can be used to check various quality criteria for every workpiece within Takt time of the production. Additionally, the flawless condition of each produced machine part can be documented and will be available as evidence in case of potential recourse claims.

The aim of the project was to implement a custom software for the inspection of a specific machine part. The focus was placed on the reliable detection and evaluation of anomalies like scratches and pores. The software solution covers both camera control, image processing, storing information in a database, communicating with the factory systems, and visualizing the evaluation results on a workstation.

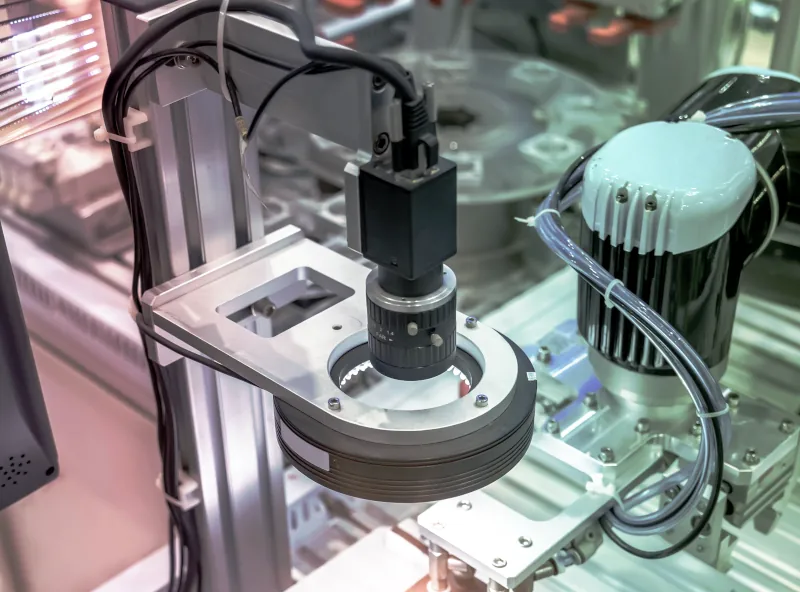

Image: Example camera installation of an inspection system (no relation to this project)

Used Technologies

The project was implemented using various technologies. Image processing is based on Python, OpenCV, and PyTorch. Camera controls are implemented among others with PyPylon. Information about machine parts and evaluation results are stored in a PostgreSQL database. The communication to the factory system (PLC) is achieved via the OPC-UA protocol. All relevant information is visualized on a web-based user interface implemented with React.

Scope of Services

During the project, the following services were provided:

- Consulting regarding potential software solutions

- Consulting and testing of the optical setting of the inspection system, cameras, lenses, and illumination

- Implementation of the software for controlling cameras, image processing, anomaly detection and evaluation, database, factory communication and user interface

- Consulting regarding server and network requirements

We look Forward to Hearing from You

Send a Message

Call by Phone

+49-391-40594560

(Mon ‒ Fri, 9am ‒ 5pm)